With a set of pre-rollers, a mold can be pushed into or pulled out of a vertical press very easily. In addition, the mold can then be removed or loaded with a forklift truck or crane.

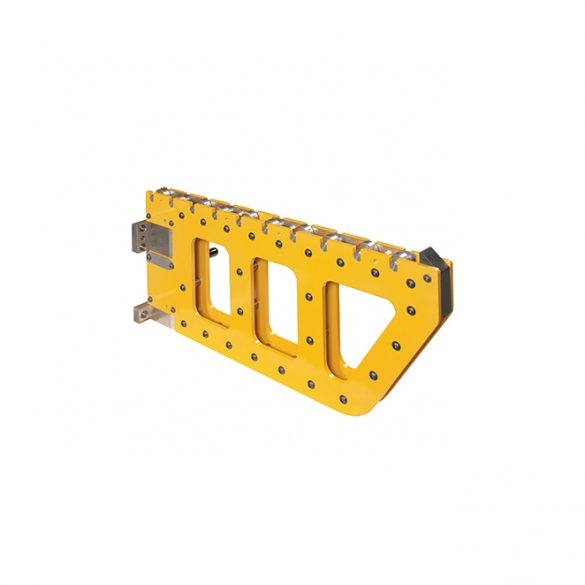

EAS PRE ROLLERS

Our die loading arms or bolster extensions, which are always fitted as a set, feature needle roller bearings with a hardened steel surface for a high load capacity.

EAS offers a wide range of pre-rollers for different mold weights and sizes. If mounting blocks are also used, the pre-rollers can be used with different presses.

A set is supplied with a yellow coating as standard.

Function

Stops at the end of the pre-rollers prevent the mold from rolling too far, but also ensure that the mold can be easily loaded onto the pre-rollers. The mounted hook allows the arm to be removed from the press if required. In addition, by providing a number of hooks, one set of pre-rollers can be used for different presses.

FIXED

Is longer and has a greater load capacity.

Comes with an adjustable support. This support is also available with rollers, for easy transport. For example, if the pre-roller is not in use and needs to be moved to a storage area.

SWIVEL

The advantage of the swivel types is that the space in front of the machine can be used efficiently because the arms can be turned away.

A double swivel is also available on request.

MOTORIZED

A motorized pre-roller is an economical alternative to a mold change table.

In this version, the pre-rollers are equipped with an electric motor that pushes or pulls the mold in or out of the machine.